Revvity | About Us

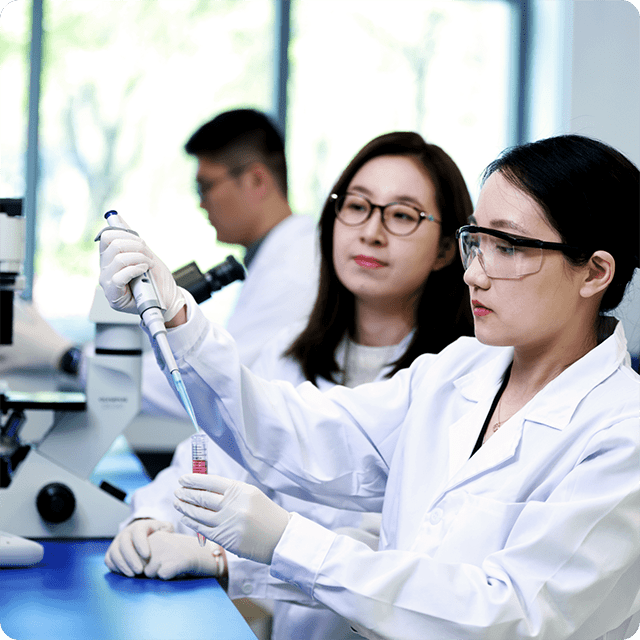

Revvity is a developer and provider of end-to-end solutions designed to help scientists, researchers, and clinicians solve the world’s greatest health challenges. We pair the enthusiasm of an industry disruptor with the experience of a longtime leader. Our diverse team of 11,000+ colleagues from around the globe are vital to our success and the reason we’re able to push boundaries in pursuit of better human health.

Find your future at Revvity.

The successful candidate will have experience and/or knowledge to:

Conducted technical analysis of manufacturing and facilities equipment installations, modifications, and enhancements to evaluate reliability and MTTF.

Coordinate maintenance technicians to troubleshoot equipment issues using a logical approach

to determine a technical solution based on the root cause.Manage Predictive and Preventive Maintenance Systems to maximize equipment availability

Work with Process Engineers to ensure Machines are capable of meeting production requirements

Conducted technical training and equipment briefings with engineers, maintenance technicians, and production technicians.

Act as local on-site representative manufacturers, contractors, and service providers

Nothing in this job description restricts management’s right to assign or reassign duties and responsibilities of this job at any time.

Basic Qualifications:

Bachelor's Degree in a STEM field

5+ years of experience servicing manufacturing equipment

OR

Associate degree in a STEM field

6+ years of experience servicing manufacturing equipment

OR

Highschool or GED

9+ years of experience servicing manufacturing equipment

Preferred Qualifications:

Experience in the Maintenance and Operation of Vacuum Process Equipment

Experience in the Maintenance and Operation of Facilities Systems

Perform hands-on support of Production Equipment

Component Reliability/ MTTF / Predictive Maintenance Planning

Logical Troubleshooting methodology Root Cause Analysis, Component Failure Analysis

-Ability to work with and manage outside contractors

Ability to Support Maintenance Technicians to implement solutions in production equipment

Experience with Facilities Systems and their specifications

HVAC

-Electrical Systems

Vacuum Component Recommendation and Selection for Upgrades

AutoCAD and SolidWorks

PLC and Control System

Support of Building Management System Architecture

#LI-CH1

Similar Jobs

- Principle Technical Support Specialist Hopkinton, MA

- Manufacturing Electrical Engineer Hopkinton, MA

- Business Development/Sales, Automated NGS Library Preparation Platforms Boston, MA, Hopkinton, MA, Providence, RI